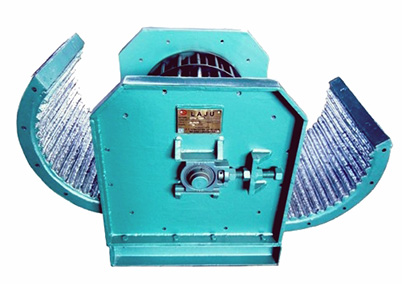

Some advantages using Laju Double Cracker Ripple Mill are:

It can crash the wet Kernel directly from depericaple drum without drying process through Nut Silo, Heater and Fan, this allows the saving of electric power and maintenance of facilities, it also trimmes the evaporation-heat cost in which can be used to the more important station such us for boiler (Sterilizer FFB) etc.

The efficiency of cracker can reach to 98%, so the loss of unstripped or half-being cracked in Clay Bath process or Hyrocyclone can be saved.

Percentage of overdried cracked kernel can be minimized. So as the dust, littering of the kernels can be reduced of the minimum of shell and kernel cracked in shatter.

The crash capacity can reach to 3 - 5 Tons/Hour for Type RM-4000 and 6 - 8 Ton/Hour for RM-6000, twice or three times proportional as conventional cracker.

This Ripple Mill is best suitable used to crash all size of fruit although without using Grading Drum, and also for crashing the very thick skin of nut or DURA NUT.

The simple construction allows the cost effective in maintenance.

The "Laju" Ripple Mill is designed in very simple construction and can be installed whereever without any great modification to the existing fabric structure.

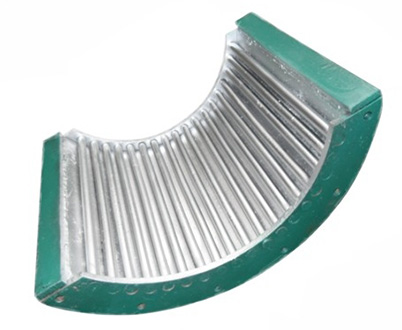

Laju Ripple Mill 3rd generation have two types of Ripple Plates supplied upon the End-users request. Ripple plates with permanent from cast steel or mild steel welded on the surface of Trapezium notches with high quality welding steel. For a selection, Ripple plates by using 18 pieces of Rods to the surface of Ripple Plate, the broken down of the Ripple Plate can be changeable with very few in number of the rods without wasting the expensive costs to replace the unit of the Ripple Plate.