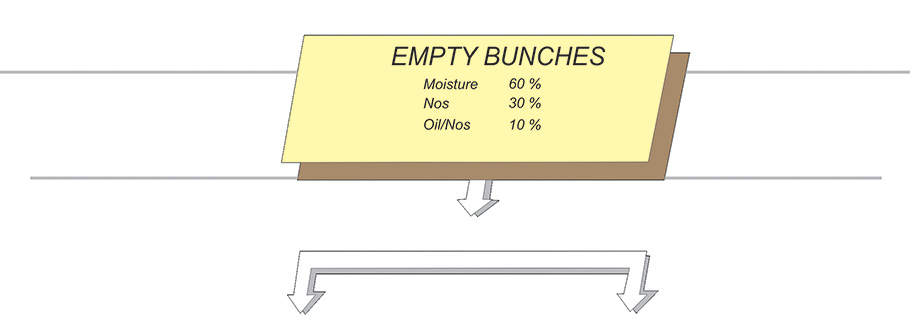

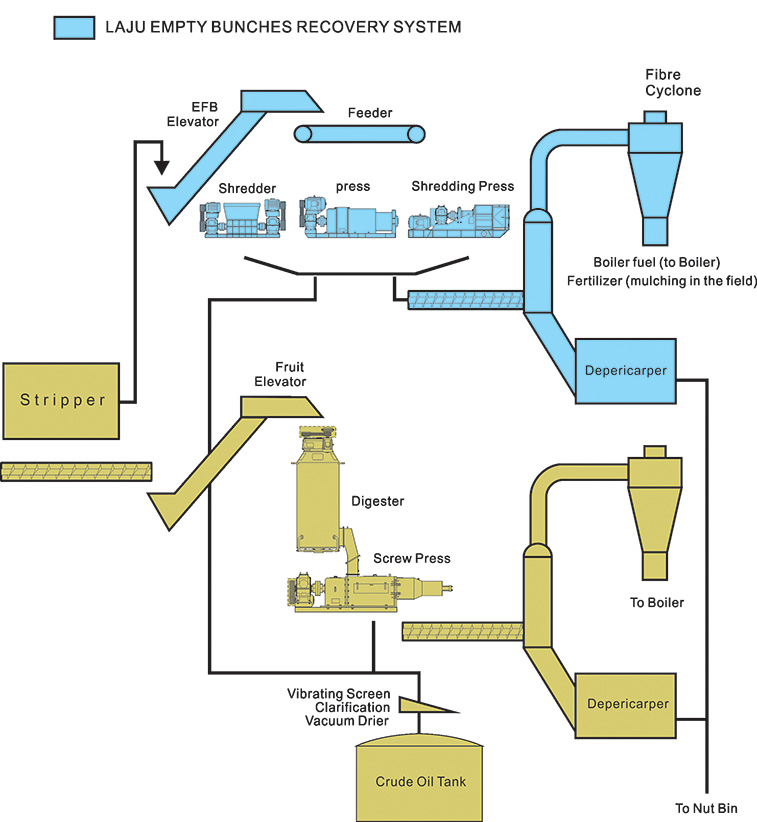

In Palm Oil Industry, empty bunches is one of the areas which has long been neglected. In traditional system, empty bunches are conveyed to incinerator for burning and the by product (bunch ash) are used as fertilizer in the field. In this process, certain percentage of oil and kernels from the unstripped/hard bunches are conveniently burnt and lost in the incinerator. Besides, incinerator is also one of the main sources of air pollution, which is extremely health hazard for the mills environment as well as the neighborhood.

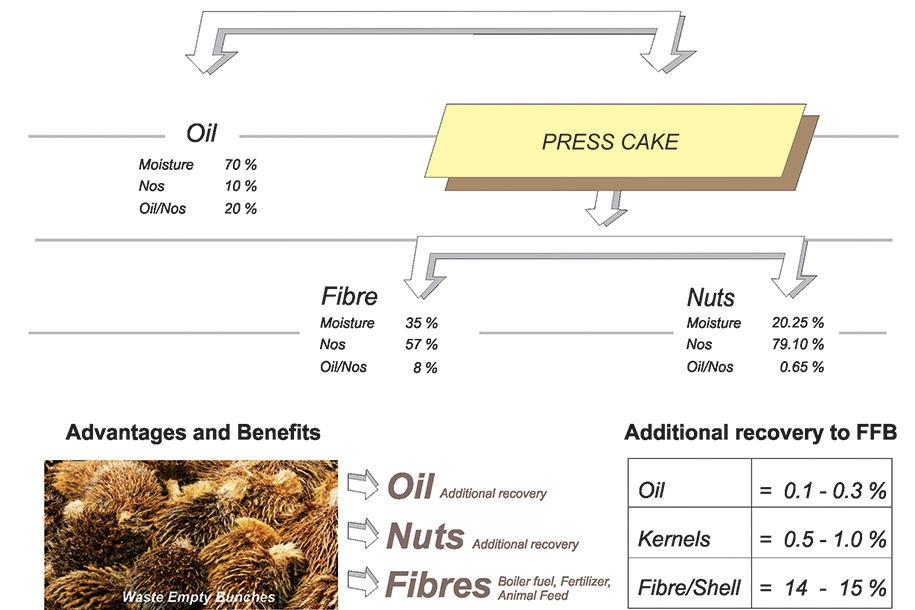

In modern mills, this process has been revolutionized by the WASTE EMPTY BUNCH RECOVERY SYSTEM, which is the latest development in the palm oil industry. The WASTE EMPTY BUNCH RECOVERY SYSTEM provides the complete treatment of empty/hard bunches whereby additional oil & kernels are recovered from these waste bunches. With this system the installation of incinerator can also be dispensed with, resulting to the complete elimination of air pollution. Furthermore, the dry fibre from these bunches can be used as additional boiler fuel for power generation, fertilizer in the field and can also be further processed to make chipboard and animal feed.

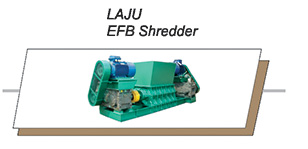

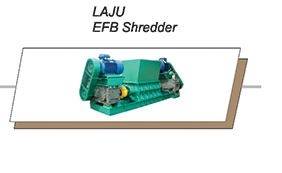

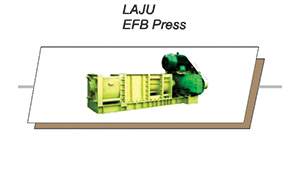

In accordance with the progress of the technological in palm oil mill today. Waste Empty Palm Oil Bunch can be recovered with LAJU EFB Shredder and EFB Press or EFB Shredding Press.

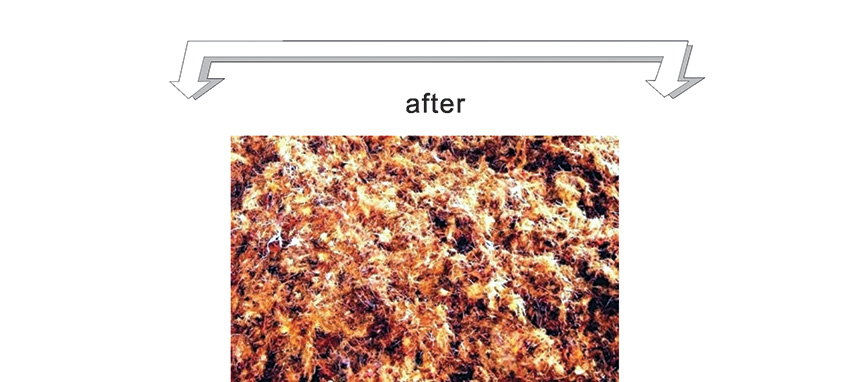

The by-product (dry fibres) of the empty bunches after proceeding by LAJU EFB Shredder and EFB Press or EFB Shredding Press acquire the advantages and benefits;

|

||

|

||

|

|

|

|

||

|

||

|

|

|

|

||

|

|

|

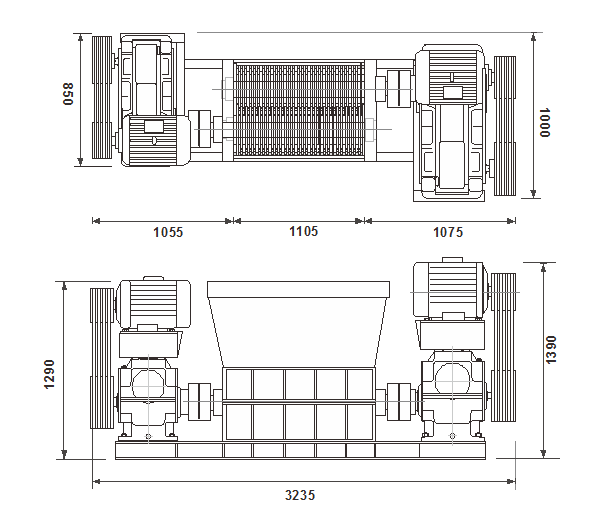

Capacity Type Worm Dimension No. Of Blade Worm's Material Number Of External Cutter External Cutter's Material Revolution Power Consumption Speed Reducer Machine Length Machine Width Machine Height |

8 - 9 Tons Empty Bunch/Hour Horizontal Double Cutters Diameter 285 mm x 14 mm Thickness 2 x 28 pieces 6 ( Six ) 550 mm x 935 mm Approx. Heat Treated Tool Steel Approx. 37 & 25 Rpm 37 kW/50 hp and 22kW/30 hp 4 Poles TEFC Motor 380V 50Hz SEW MC3PLSF06 Ratio 40:1 & MC3PLSF04 Ratio 60:1 or equivalent 3235 mm Approx. 1000 mm Approx. 1390 mm Approx. |

|

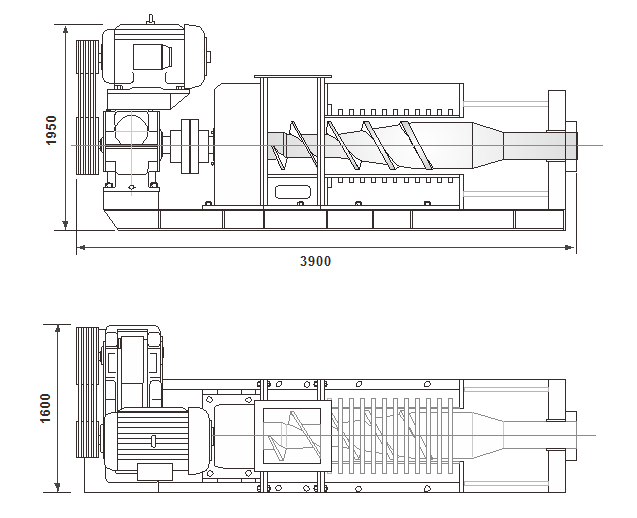

Capacity Type Worm Dimension No. Of Flight Worm's Material Revolution Power Consumption Speed Reducer Machine Length Machine Width Machine Height |

8 - 9 Tons Empty Bunch/Hour Horizontal Mono Screw Worm Diameter 430 mm x 2745 mm 5 ( Five ) CrMoly with Hard Facing of Last Flight Approx. 16 - 18 Rpm 75 kW/100 hp 4 Poles TEFC Motor 380V 50Hz SEW M3PSF60KPD Ratio 56 : 1 or equivalent 3900 mm Approx. 1600 mm Approx. 1950 mm Approx. |

|

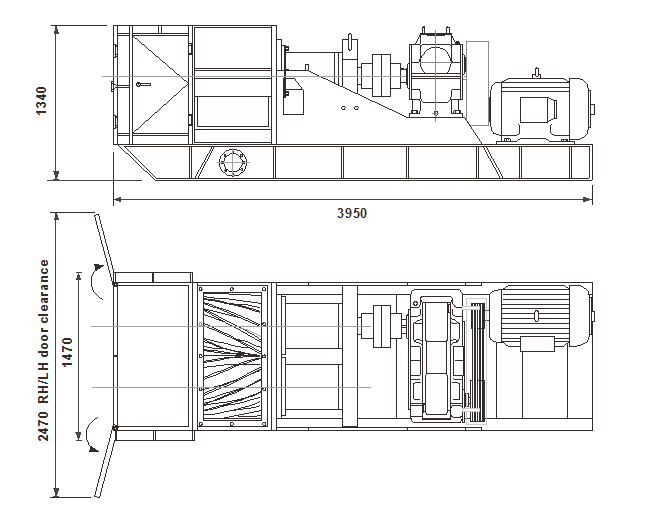

Capacity Type Worm Dimension No. Of Blade Worm's Material Number Of External Cutter External Cutter's Material Revolution Power Consumption Speed Reducer Machine Length Machine Width Machine Height |

8 - 9 Tons Empty Bunch/Hour Horizontal Twin ( Blade ) Worms Diameter 475 mm x 725 mm 2 x 12 ( Twelve ) CrMoly with Hard Face Teeth 2 x 4 ( Four ) Heat Treated Tool Steel Approx. 16 & 20 Rpm 75 kW/100 hp 4 Poles TEFC Motor 380V 50Hz SEW M3PSF60KPD Ratio 56 : 1 or equivalent 3950 mm Approx. 1470 mm Approx. 1340 mm Approx. |